We specialize in the custom machines. Pick a standard machine and we can design it for your specific needs.

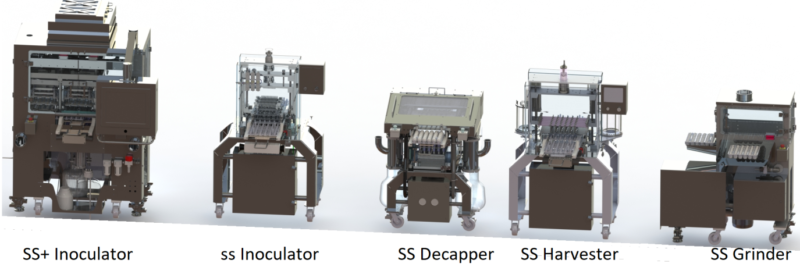

Smart Sized Automatics

Especially Designed for Small and Medium production facilities.

Also very useful for Pilot processing.

Other available Smart Sized Systems:

- Individual egg harvester site cart with or without cleaning

- Customized tray configurations possible

- Combinations of SSS systems. (Also known as Smart Sized COMBIMachines)

- Embryo harvesting

- Desktop Single Egg Decapper

Add ons:

Add ons:

PDF printing, data logging data for exporting (SCADA)

Remote connection for trouble shooting or upgrading

Removing 2 hand safety for faster automation

Servos or Air cylinders drives

End or infeed carts

Airflows system, LAF & FFU

Spray Station

UV sterilization

Fumigation chambers

CIP or WIP

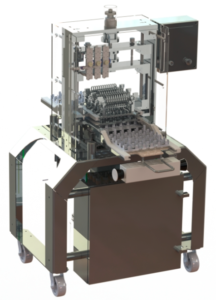

Smart Sized Automatic Egg Inoculators (SSI) & (SSI+)

SSI

SSI

SSI+

SSI+

Description

SSI

- Speed: 330 trays an hour. —————————–>11,000-14,000 eggs an hour

- Footprint: 121 cm x 106 cm (48 inches x 43 inches).

- On request: Infeed “Pull back” or “Push through” design.

SSI+

- Speed: 560 trays an hour.——————————->20,000-24,000 eggs an hour

- Footprint: 126 cm x 121 cm (50 inches x 48 inches).

- On request: Infeed “Pull back” or “Push through” design.

- Airflows system maintains well above a grad C biosafety security.

Both Systems

- Plug and play with all controls.

- Doses can be as small as 0.1ml for each egg with a high accuracy.

- Remote connection for trouble shooting or upgrading.

- All highest grade Stainless Steel Needles & hubs.

- Ideal for small to medium-sized production runs.

- This system is an Automatic Inoculating machine without the conveyor system.

- Features include egg lifting, punch and needle cleaning, and automatic inoculating.

- Only requires one person to operate.

- The system doses inoculum into each egg with high accuracy.

- The needle is sanitized in a bath after every inoculation.

- Lifter blocks included.

- All daily cleaning parts can be removed in less then 10 minutes with no tools.

- Produced according to highest standards with focus on pharmaceutical cleanability.

- WIP

Smart Sized Automatic Egg Decapper (SSD)

Description

Description

- Plug and play with all controls.

- Speed: 400 trays an hour.————————->14,000-17,000 eggs an hour

- Footprint: 112 cm x 122 (45 inches x 48 inches).

- Decapper Success rate==99.74% & Automatic blade washing after each decap

- Ideal for small to medium-sized production runs.

- The system removes and discards the top portion of the eggshell.

- Only requires one person to operate.

- Features include egg lifting, automatic decapping and blade spraying.

- Optional infeed pull back or push through design.

- Safety interlocks with covers and doors built in.

- All daily cleaning parts can be removed in less than 10 minutes with no tools.

- Produced according to highest standards with focus on pharmaceutical cleanability.

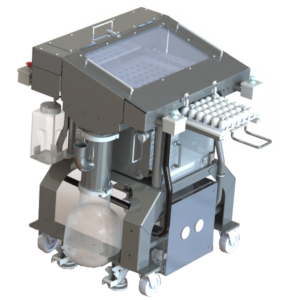

Smart Sized Automatic Egg Harvester (SSH)

Description

Description

- Plug and play with all controls.

- Speed: 400 trays ————————————–>14,000-17,000 eggs an hour

- Footprint: 108 cm x 121 cm (43 inches x 48 inches).

- Ideal for small to medium-sized production runs.

- Only requires one person to operate.

- Remote connection for trouble shooting or upgrading.

- Aspiration is used to harvest the allantoic fluid into an aliquot.

- Optional infeed pull back or push through design.

- Safety interlocks with covers and doors built in.

- All daily cleaning parts can be removed in less then 10 minutes with no tools.

- Produced according to highest standards with focus on pharmaceutical cleanability.

- Individual needle suction using aspiration.

- WIP.

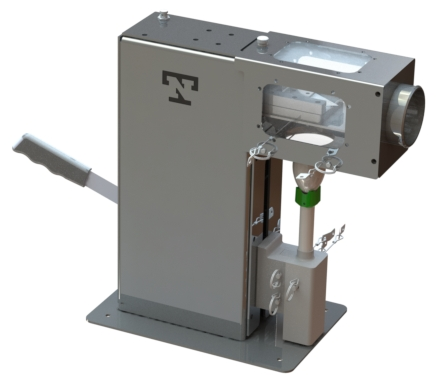

Smart Sized Grinder (SSG)

Description

Description

- Plug and play with all controls.

- Speed: 900 trays.————————————->40,000 eggs an hour

- Footprint: 100 cm x 125 cm (40 inches x 50 inches).

- Ideal for small to medium-sized production runs.

- Only requires one person to operate.

- Grinder cart and pumps waste.

- 2 chute design, fresh water button, interval tray grinding, variable speed.

- Noise Level: < 80 db with stainless steel noise insulated cover.

- High output pump and grinder.

- All daily cleaning parts can be removed in less then 10 minutes with no tools.

- Produced according to highest standards with focus on pharmaceutical cleanability.

Automatics

Other Automatics:

Other Automatics:

Tray Washer

Trolley Unloaders/ Loaders

Candlers

Individual egg harvester site carts with or without cleaning

Custom tray automatic

Conveyors

Tray stackers/Destackers

Add ons:

End or infeed conveyors

End or infeed carts

Airflow systems

Fumigation chambers

UV sanitation

Spray stations

CIP & WIP

Fully Automatic Egg Harvesters

- FHC Fully Automatic Harvester COMPACT

- FHC+ Fully Automatic Harvester COMPACT+

- FHS Fully Automatic High Speed Harvester SUPERIOR FHS

- FHE Fully Automatic High Speed Harvester EXTREME FHE

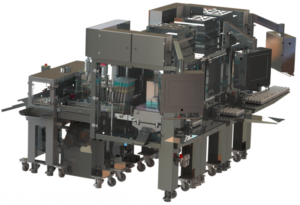

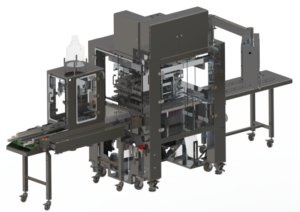

FHC

FHC+

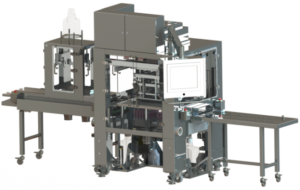

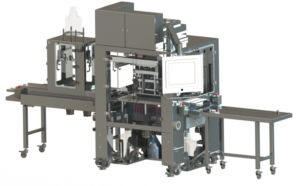

FHS

FHE

Fully Automatic Egg Harvesters COMPACT FHC & FHC+

FHC Harvester Compact:

- Footprint:: 287 cm x 147 cm (113 inch x 58 inch)

Ideal for small areas: Worlds smallest Automated Harvester.

FHC+ Harvester Compact+:

- Footprint: 337 cm x 147 cm (133 inch x 58 inch):

Similar to FHC but a viewing area after Harvesting.

For Both Designs

- Fully Automatic plug and play with all controls.

- AI vision system technology with best accuracy in the world.AI Vision Success rate=99.05%

- Decapper Success rate==99.74% & Automatic blade washing after each decap

- Speed: Both Automatic Harvesters do have a variable speed of 450 trays an hour.—->16,000-20,000 eggs an hour

- Remote connection for trouble shooting or upgrading.

- Design includes: Decapper, Vision Inspection, Harvesting, and Grinding/Pumping.

- All daily cleaning parts can be removed in under 30 minutes with no tools.

- Vision inspection system: automatically detects bad eggs and discards them from

the harvesting process. - High resolution camera with custom lighting in a camera box.

- Human interaction included with touch screen.

- PDF printing, data logging, data for exporting.

- Designed for easy cleaning and maintenance.

- Mobile and lock down design easy to move and disconnect.

- Designed to minimize human egg handling to ensure no bioburden.

- Noise Level: < 80 db with high power.

- Precise servos used for tray movements.

- Produced according to highest standards with focus on pharmaceutical cleanability.

- WIP & CIP.

Full Automatic Egg Harvesters High Speed SUPERIOR FHS & EXTREME FHE

FHS SUPERIOR:

Speed: 900 trays per hour.—————————–>32,000-40,000 eggs per hour

Footprint: 340 cm x 198 cm (134 inch x 78 inch).

FHE EXTREME:

Speed: 1,350 trays per hour.—————————>48,000-57,000 eggs per hour

Footprint: 340 cm x 282 cm (134 inch x 111 inch).

For Both Designs:

- Fully Automatic plug and play with all controls.

- AI vision system technology with best accuracy in the world. AI Vision Success rate=99.05%

- Decapper Success rate==99.74% & Automatic blade washing after each decap

- Ideal for automating the harvesting process at high productions facilities.

- Remote connection for trouble shooting or upgrading.

- Design includes: Decapper, Vision Inspection, Harvesting, and Grinding/Pumping.

- All daily cleaning parts can be removed in under 1-2 hours with no tools.

- Vision inspection system: automatically detects bad eggs and discarded from the harvesting process.

- High resolution camera with custom lighting in a camera box.

- Human interaction included with touch screen.

- PDF printing, data logging, data for exporting.

- Designed for easy cleaning and maintenance.

- Mobile and lock down design easy to move and disconnect.

- Designed to minimize human egg handling to ensure no bioburden .

- Noise Level: < 80 db with high power.

- Precise servos used for tray movements.

- Produced according to highest standards with focus on pharmaceutical cleanability.

- WIP & CIP.

Fully Automatic High Speed Egg Inoculators SUPERIOR FIS & EXTREME FIE

FIS

Superior FIS

FIE

Extreme FIE

Description FIS & FIE

FIS Auto Inoculator

- Speed:,1,250 trays an hour.—————————————->40,000-50,000 eggs per hour

- Footprint: 456 cm x 178 cm (180 inch x 70 inch).

- Ideal for small areas needing high inoculation production.

FIE Auto Inoculator:

- Speed: 2,000 trays an hour. —————————————>50,000-80,000 eggs per hour

- Footprint: 548 cm x 178 cm (216 inch x 70 inch).

- Ideal for automating the Inoculating process at high productions facilities.

For Both Designs:

- Fully Automatic plug and play with all controls.

- Airflows system maintains well above a grad C biosafety security.

- Design includes air flow, sanitizing eggs, inoculating, and needle sanitation.

- All daily cleaning parts can be removed in under 1-2 hours with no tools.

- Doses can be as small as 0.1ml for each egg with a high accuracy.

- Remote connection for trouble shooting or upgrading.

- PDF printing, data logging, data for exporting.

- Designed for easy cleaning and maintenance.

- Mobile and lock down design.

- Designed to minimize human egg handling to ensure no bioburden.

- Noise Level: < 70 db.

- All highest grade Stainless Steel Needles & hubs.

- Produced according to highest standards with focus on pharmaceutical cleanability.

- The highest grade stainless steel for product contact parts.

- WIP & CIP.

NT General Specifications:

- Designs are done in Solidworks 3D modeling.

- Controls are done in Siemens programming other optional.

- Electrical and wiring follow UL standards.

- Document packages FDS, OMM, FAT, SAT, IOQ.

- Design will be constructed for the Pharmaceutical and Food environment.

- All Machines will be 90 % designed and constructed in 304 or 316L stainless steel.

- Any anodized aluminum on cylinders away from product and cleaning.

- Plastics will be chemical resistant and class 6.

- Total system designed in a sanitary manor.

- Welds are all sanitary welds and done by a certified welder.

- Welds are used with low carbon s/s rods are polished and passivated after finished.

- Welds will have no open gaps, pits, cracks, or holes for viruses to live.

- All machinery to be tested and analyzed for defects before shipping.

- All surfaces will have a roughness of 0.8um Ra (cla 32). or better.

- Product contact parts will have a roughness of 0.4um Ra (cla 16). or better.

- Adjustable legs for levelling the total system.

- All areas of the machine are fully accessible.

- Remote connection for trouble shooting or upgrading.

- ISO 9001 standards.

- Easy access to whole system by hinged removable side doors.

- Assembled, R&D and testing.

- Pharmaceutical certified material used.